What to Expect from a Quality 3D Print

Fused Deposition Modeling (FDM/FFF) 3D printing has revolutionized how we prototype and manufacture parts. However, like any manufacturing process, this technology has unique characteristics that are perfectly normal and expected.

Many customers new to 3D printing wonder what constitutes a quality print. This guide was created to help you distinguish between characteristics inherent to the FDM process and defects that compromise part functionality.

By understanding these differences, you can make more informed decisions about your projects and have realistic expectations about final results.

How FDM Printing Works

FDM technology works by extruding heated plastic filament, layer by layer, to build a three-dimensional part. This additive process means that each layer of material is deposited on top of the previous one, gradually creating the desired shape.

Due to this layer-by-layer construction nature, there are visual and tactile characteristics that are normal and expected. These do not indicate poor quality - they are simply the signature of the manufacturing process.

Expected Characteristics in Quality Prints

The following characteristics are completely normal and do not compromise the structural integrity, functionality, or durability of your parts:

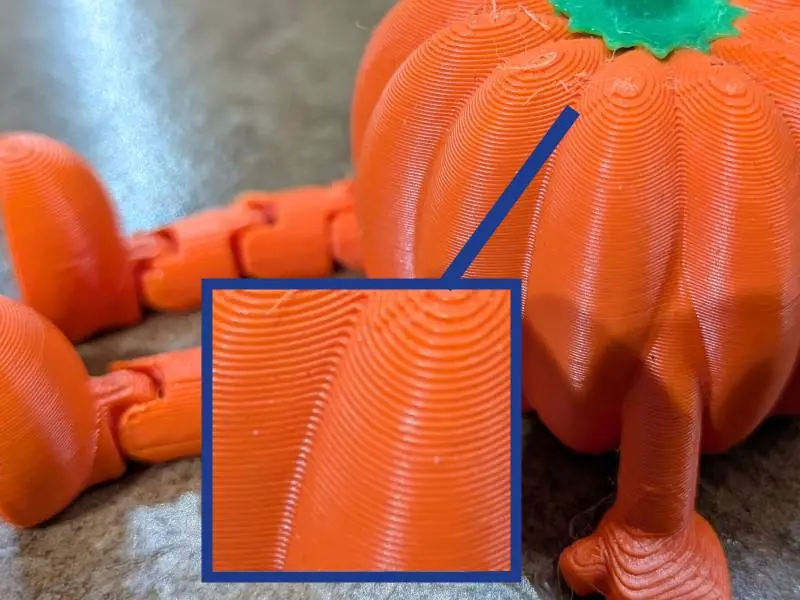

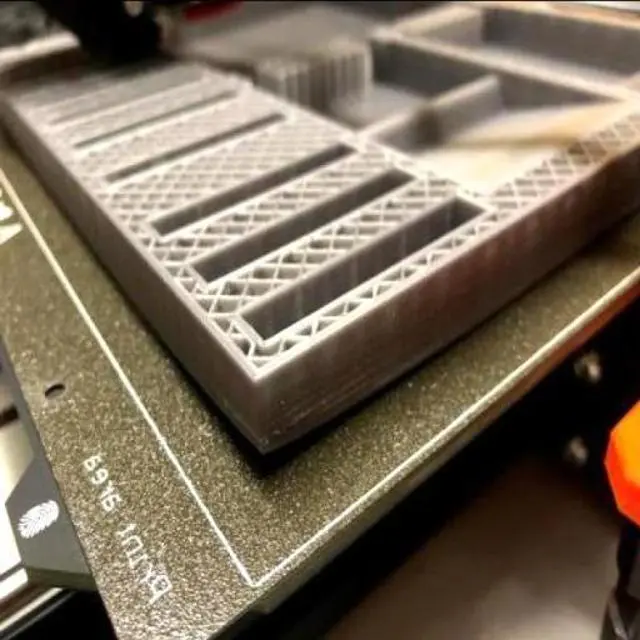

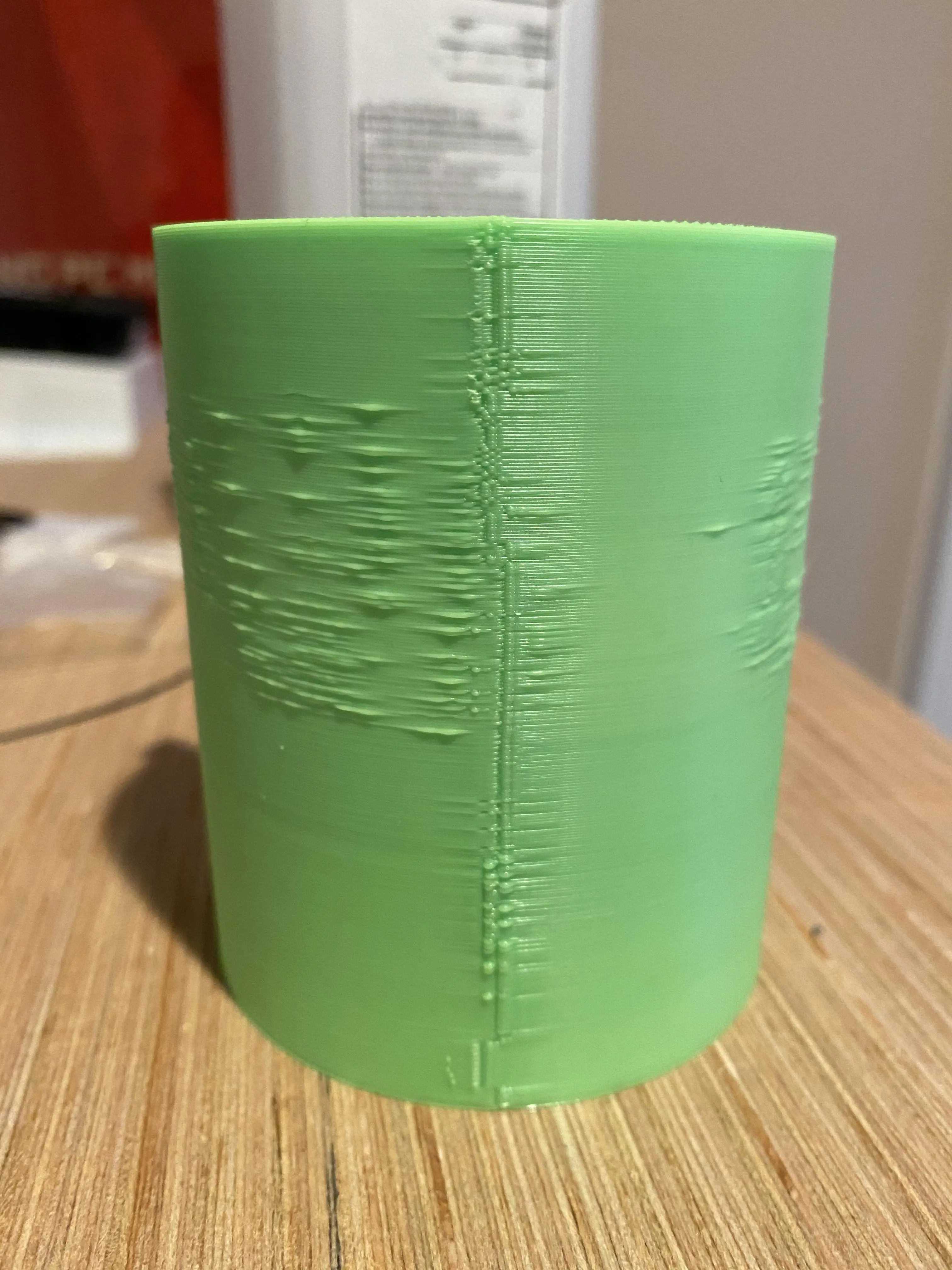

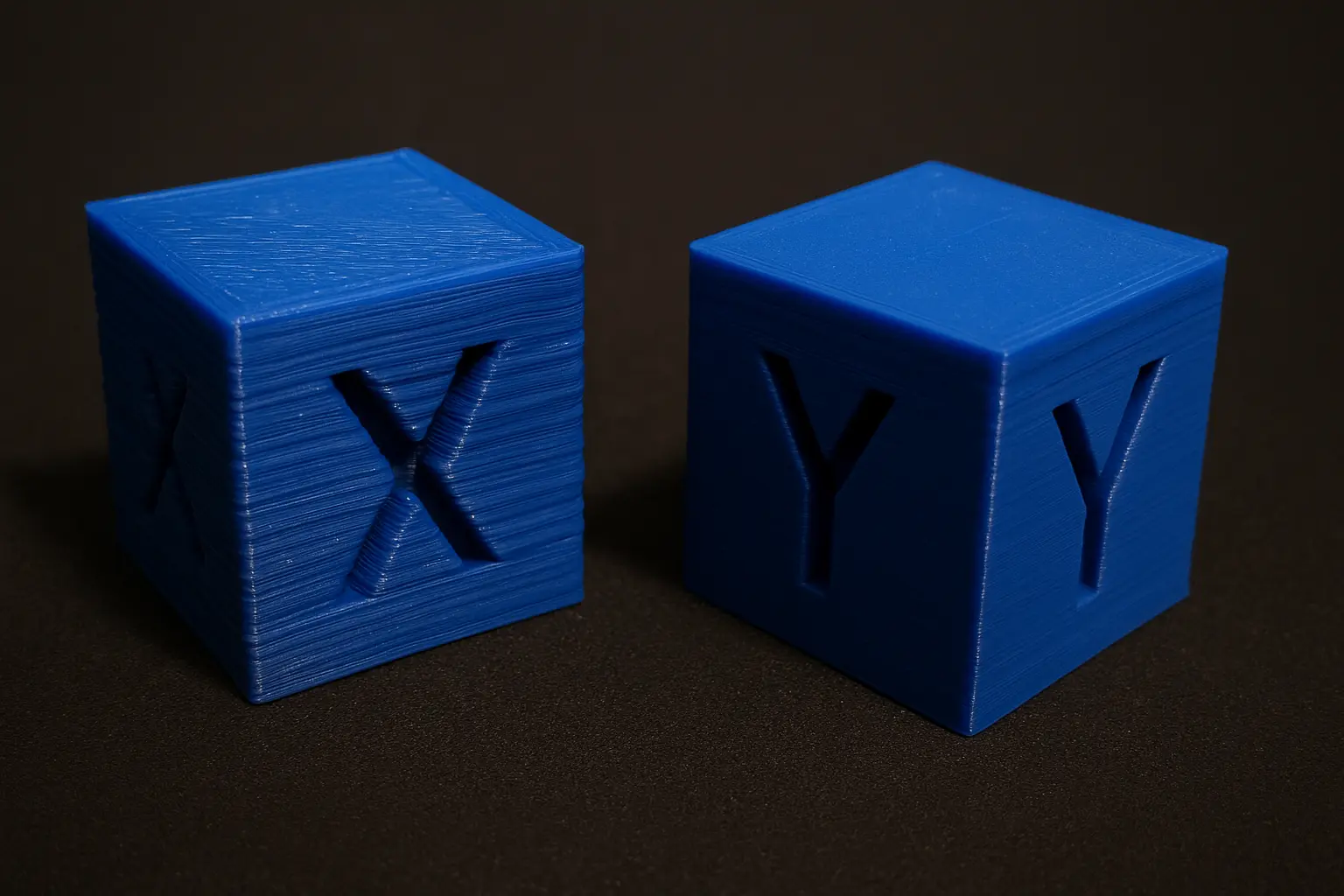

Visible Layer Lines

Layer lines are the most recognizable feature of FDM printing. Each line represents an individual layer of deposited material. The visibility of these lines depends on the chosen layer height (typically between 0.1mm and 0.3mm).

Thinner layers (0.1mm) result in a smoother surface but significantly increase print time. Thicker layers (0.3mm) are faster but more visible. In a quality print, these lines should be uniform and consistent.

Why It's Normal:

It's the fundamental nature of the FDM process. These lines ensure good adhesion between layers and are a sign that the printer is depositing material consistently.

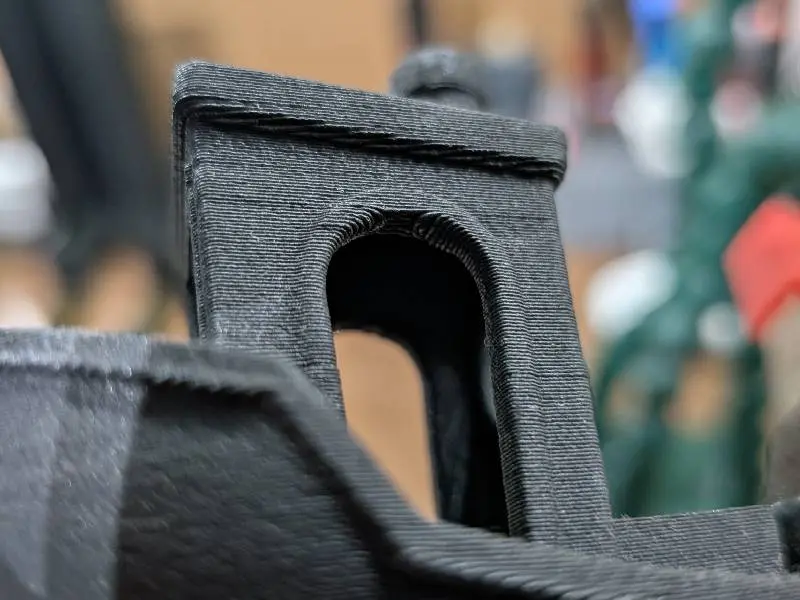

Support Marks

Support structures are necessary to print geometries with angles greater than 45° or suspended areas. After printing, these supports are removed manually or through chemical dissolution.

Areas where supports were in contact with the part may show a slightly different texture or small marks. With proper post-processing (sanding, acetone vapor, etc.), these marks can be minimized or eliminated.

Why It's Normal:

Complex parts frequently require supports. The resulting surface marks do not affect the part's strength or functionality and can be addressed in post-processing.

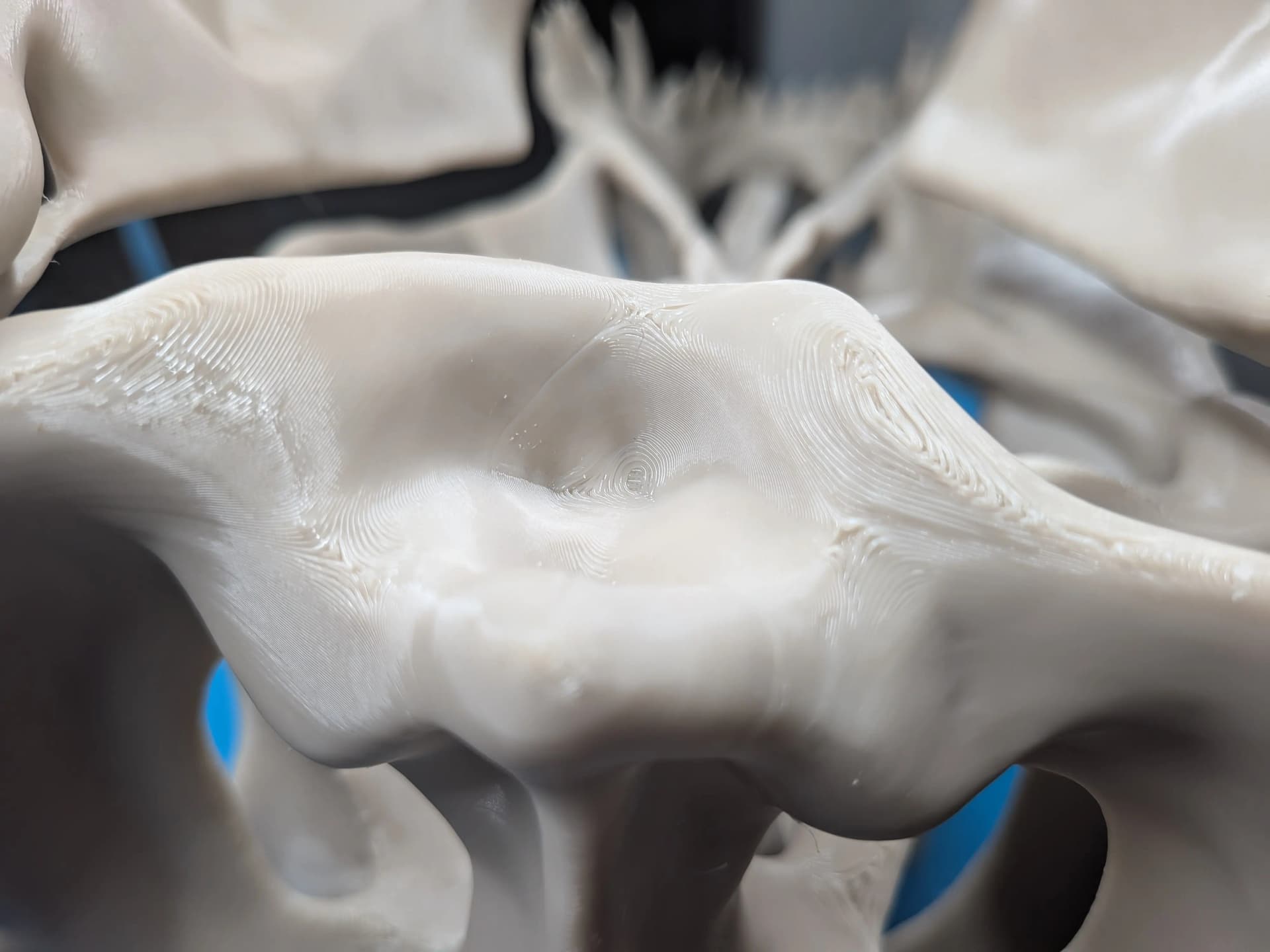

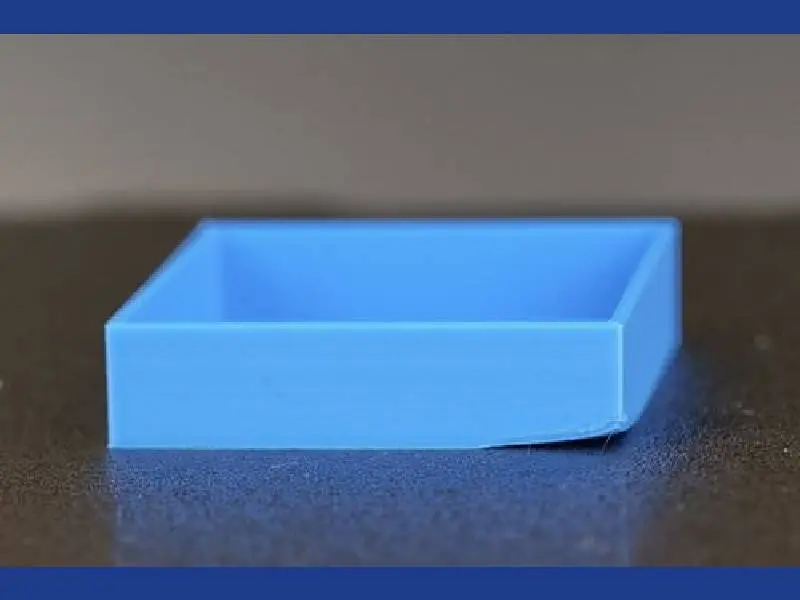

Bottom / Top Surfaces Texture

The first layer of the print is deposited directly onto the build platform (bed). To ensure proper adhesion, this surface usually has texture, which is transferred to the part's first layer.

Depending on the type of print surface used (glass, PEI, BuildTak, etc.), the texture may vary. A smooth surface indicates glass; a rougher texture indicates textured surfaces that offer better adhesion.

Why It's Normal:

The base texture is evidence of excellent first layer adhesion, crucial to avoid detachment during printing. This adhesion ensures dimensional accuracy.

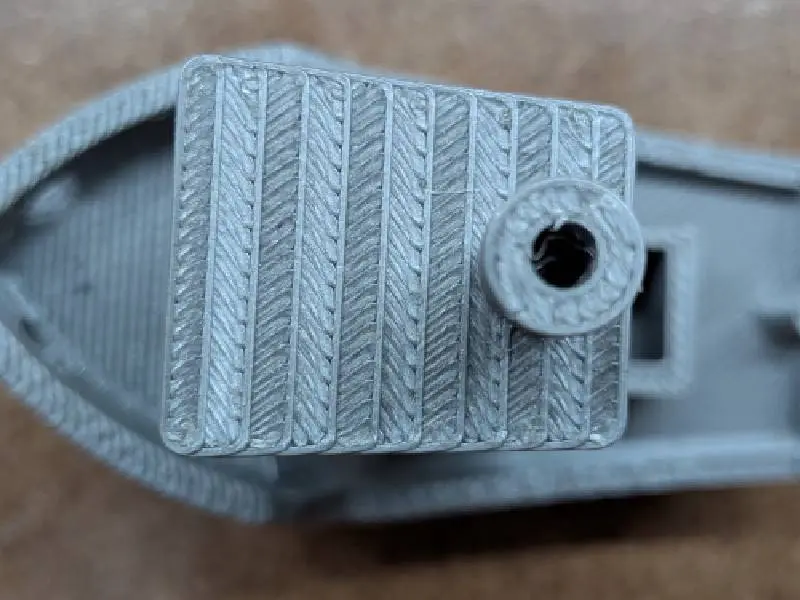

Dimensional Tolerances

FDM printing has typical tolerances of ±0.2mm to ±0.5mm, depending on printer quality, calibration, material, and part geometry. This means final dimensions may vary slightly from the original CAD model.

For projects requiring precise fits or assemblies, these tolerances should be considered in design. Often, holes are designed slightly smaller to be reamed later, or fits are designed with appropriate clearances.

Why It's Normal:

Thermal variations during printing, material shrinkage during cooling, and the printer's own resolution contribute to these tolerances. These are industry-standard values for FDM.

What You Shouldn't Accept as Quality Results

Unlike the expected characteristics described above, the following defects seriously compromise the quality, functionality, and durability of printed parts. These are production problems that should result in part reprinting:

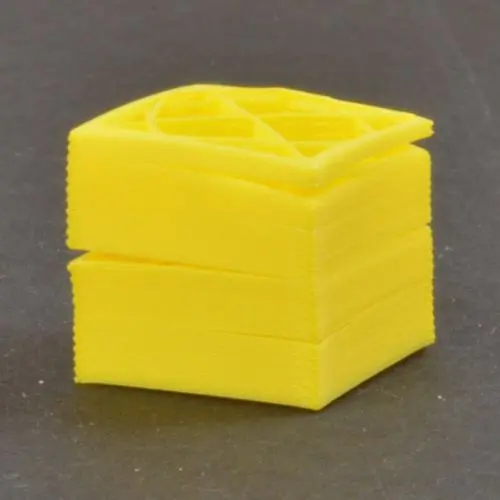

Warping

Deformation from uneven cooling that warps part edges, compromising dimensions and assembly.

Douro Make's Commitment to Quality

At Douro Make, every print undergoes rigorous quality control inspection before shipping. Our technical team checks dimensions, structural integrity, surface quality, and functionality.

If we identify any defect that compromises your part's quality - warping, delamination, dimensional problems, or significant surface defects - the part is reprinted at no additional cost to you.

Our goal is not just to deliver a printed part, but to ensure it meets your project requirements. Your satisfaction and application success are our top priority.

Conclusion: Quality and Realistic Expectations

Understanding the natural characteristics of FDM printing allows you to correctly assess your parts' quality and have realistic expectations about results.

Remember: visible layer lines, small support marks, base texture, and dimensional tolerances within standards are completely normal. Warping, delamination, severe irregularities, and excessive dimensional inaccuracies are not acceptable.

With this knowledge, you can make informed decisions about your projects and trust that Douro Make will deliver parts that meet the highest industry quality standards.